Non-Destructive Testing (NDT) is an essential part of the electronics manufacturing process. It can be used to ensure product reliability, safety, and efficiency without damaging any of the components. An Example of NDT is to use x-ray to see what cannot be seen by eye.

You can read more specifically about non-destructive x-ray testing here.

This article explores the various benefits of NDT in the context of electronics, where there is no room for errors when it comes to precision and quality.

What are the Key Benefits of using Non-Destructive Testing in Electronics Manufacturing?

Using Non-Destructive Testing to Enhance Product Reliability through Early Fault Detection

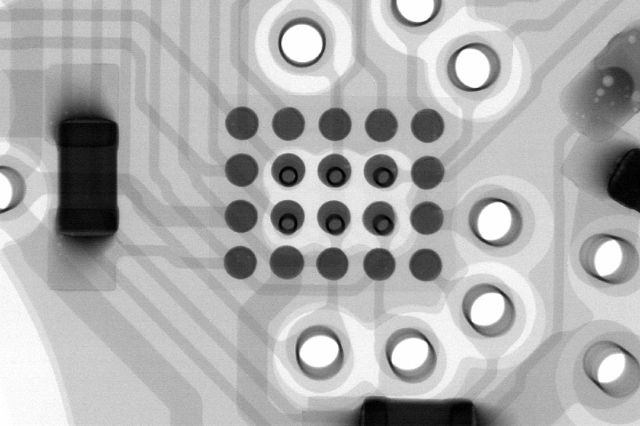

One of the biggest benefits of NDT is the Early Detection of Defects. Using NDT methods like ultrasonic testing and X-ray imaging throughout the manufacturing process, allows manufacturers to detect internal and external defects early in the production process. This early detection allows manufacturers to address potential failures before products reach the market, significantly enhancing product reliability.

Advanced NDT techniques provide high-resolution insights into complex electronic components, such as circuit boards and microchips. These are crucial for ensuring that each part meets strict quality standards.

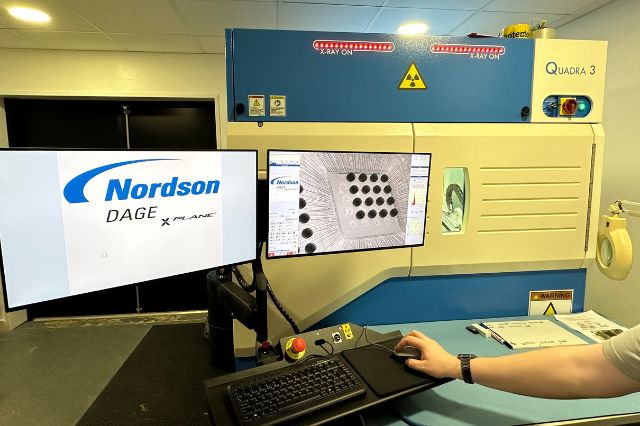

At The Electronics Group we can provide such high-resolution images and detailed reports in compliance with IPC standards using our state-of-the-art Nordson Dage Quadra 3 X-Ray machine. By sending us samples early in the manufacturing process we can assist in early fault detections to save you time and money in the long run.

Non-Destructive Testing for Cost Reduction and Efficiency

Non-destructive testing methods allow for quicker inspections and continuous production line assessments without the need for disassembly. This streamlining of the production process is one of the major benefits of NDT. It reduces downtime and enhances overall manufacturing efficiency.

By ensuring that all electronic products are defect-free before shipment, one of the key benefits of NDT is that it can help in reducing warranty claims and associated costs. Ultimately protecting the manufacturer’s bottom line and reputation.

Optimising Quality Control is another important benefit of NDT. By enlisting the non-destructive testing services of a company like The Electronics Group, electronics manufacturers can maintain a consistently high quality of production. By optimising their quality control processes and implementing NDT as standard procedure early in the production process, manufacturers can reduce the likelihood of costly recalls or customer dissatisfaction.

Supporting Innovation in Electronics Design with Non-Destructive Testing

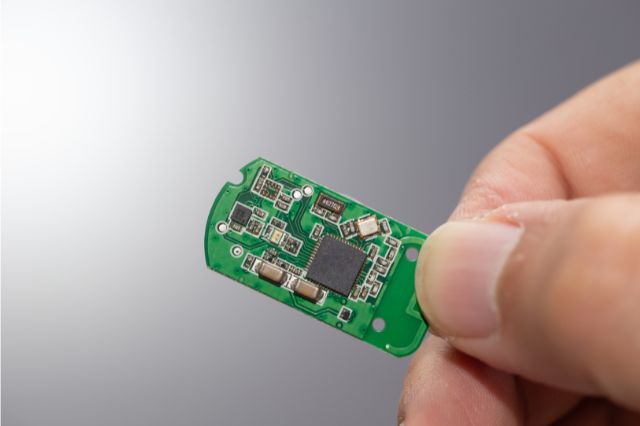

Non-destructive testing plays a crucial role in the manufacturing of innovative electronic products with complex designs. It can ensure the integrity and functionality of new materials and complex assemblies without disrupting or damaging the components.

As electronic devices continue to get smaller, NDT provides the necessary tools to accurately assess and check microscale components. All of which is essential for the miniaturisation trend in electronics.

Improving Safety and Compliance with Non-Destructive Testing

One of the most important benefits of NDT is that it helps ensure that electronic products comply with international safety and IPC standards. Complying with IPC standards is crucial for devices intended for critical applications. For example, in areas such as medical, automotive, and aerospace industries. By using various Non-Destructive testing methods, manufacturers can ensure products are made to meet the highest standards throughout the production process.

You can read more on the specifics of the IPC class standards here.

Regular NDT inspections help manufacturers adhere to strict regulatory requirements, avoiding legal and financial penalties. This extra step in risk management is essential for maintaining high safety and quality standards.

Sustainability and Environmental Responsibility of Non-Destructive Testing

Non-destructive testing methods contribute significantly to sustainability. It allows for the reduction of waste that is associated with defective products. It also creates an opportunity for the components detected as flawed during the inspection process to be recycled.

By ensuring that only the most robust components are used, and no faults are present during manufacturing, NDT also helps in extending the lifespan of electronic products. This inevitably leads to a reduction in electronic waste and promotes environmental sustainability. Making sustainable working practices one of the most important benefits of non-destructive testing.

Benefits of Non-Destructive Testing with The Electronics Group

Non-Destructive Testing provides undeniable benefits in electronics manufacturing, from enhancing product quality and reliability to supporting sustainability. As technology evolves, the role of NDT is set to become more integral, ensuring that manufacturing processes remain efficient, safe, and environmentally responsible.

Put your trust in us at The Electronics Group to assist you with your NDT needs. Using our state-of-the-art Nordson Dage Quadra 3 X-Ray machine we can work together to ensure your products meet the standards you require. Detecting faults early, saving you time, money and resources.

Take a look at our Inspection services or get in touch with our team today to discuss your specific needs and how we can work together to get the job done.