Electronics Inspection Services

Specialist Non-Destructive Testing and X-Ray Inspection for Electronics Assemblies

The Electronics Group (EGL) offers a wide range of specialist electronics inspection services to support manufacturers, assemblers and engineers across the UK. From visual and scope-aided inspection to advanced X-ray analysis, our non-destructive testing services are delivered by trained professionals to IPC standards.

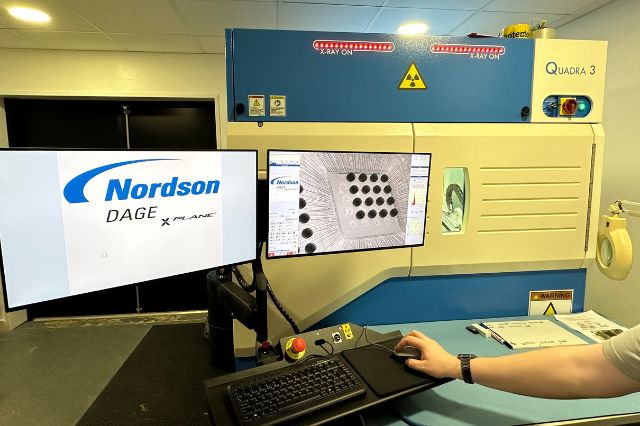

We use industry-leading equipment — including our state-of-the-art Nordson Dage Quadra 3 X-ray system — to help you identify faults, ensure product quality, and maintain high performance across your electronic assemblies. All of our inspection of electronics is non-destructive, meaning your products may be re-used, reworked, or repaired – rather than wasted.

Electronics Inspection Services - X-Ray Inspection

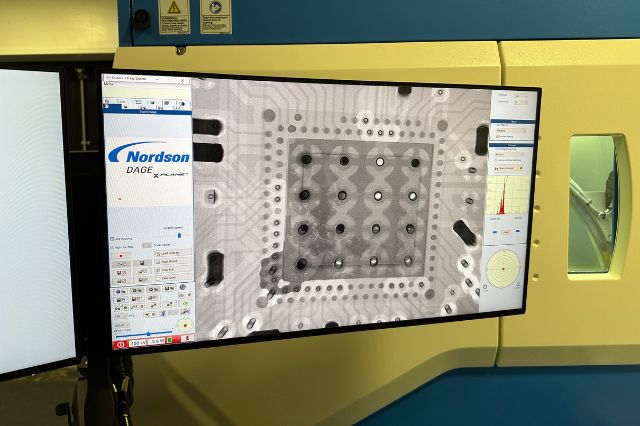

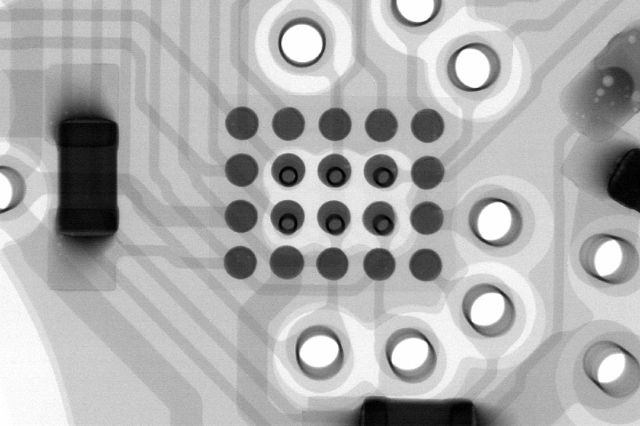

In 2022, EGL invested in the Nordson Dage Quadra 3 X-ray machine to enhance our technical inspection capabilities. Our system is designed for inspection of BGA (Ball Grid Array), µBGA and CSP (Chip Scale Packaging) inspection. Plus multilayer board inspection and PCBA/ electronic assembly solder joint inspection – including void analysis and short circuits.

Many modern assemblies use BGA, QFN, CSP and flip-chip devices that simply cannot be visually inspected, meaning non-destructive testing methods such as high resolution X-ray analysis is the only way to investigate problems, or even give customers peace of mind before delivery of their products.

X-Ray Inspection Applications

Our X-ray inspection services are used to identify:

- Fractures, cracks, and faults in components or materials

- Counterfeit or damaged components

- Dry joints and poor solder connections

- Solder bridges or shorts

- Voiding (including full analysis reporting)

- Component misalignment or placement issues

- Incorrect reflow temperature profiles

We’ve been supporting the electronics industry for many years with fast, reliable non-destructive testing and inspection. Our X-ray services have played a key role in helping manufacturers produce high-quality assemblies — from prototypes and potted boards to complex multi-layer builds, cable and wire harnesses, large batch runs, and even RF filter void analysis. Whatever you’re working on, we’re here to help.

What Else Can We X-Ray?

We are not limited to inspecting PCBs and electronics components. If you have a product or part that you need to inspect internally without compromising it, then this service is for you.

In the past we have received various objects for X-Ray inspection from cooking appliances to money counters. Whatever your requirement is, no matter how niche, give us a call to see how we can help.

X-Ray Equipment Specification

Our Nordson Dage Quadra 3 electronics inspection system offers fine detailed imaging with the ability to inspect thick and dense samples, with magnification of up to 6000x. Allowing us to capture any defects that are otherwise invisible to the naked eye.

Nordson Dage Quadra 3 Specifications:

- Micron-level resolution

- 12” x 12” scan area

- 6000x magnification

- 360° sample rotation

- 160kV high-penetration X-ray source

- True concentric imaging (fixed ROI view) – you can choose a Region of Interest (ROI) and position it in the centre of the screen. Then, under any combination of rotate, tilt or magnification, the ROI remains locked to the centre of the field of view

- Parallel tracking for fast BGA inspection – once you have the right combination of tilt and rotate to view a BGA ball, you can then run along the row of BGA balls, easily checking for failures.

- User-friendly software interface

- 5kg weight capacity

Additional Technical Inspection Services

Beyond our X-ray inspection services, our Leeds facility is equipped with a range of advanced tools for non-destructive electronics testing:

- Visual and Scope-Aided Inspection

Using Vision Engineering scopes and specialised equipment, we provide detailed inspection of PCBs, solder joints, and components.

- ESD Awareness and Auditing

We help businesses reduce the risk of electrostatic discharge through on-site ESD assessments and process reviews.

- Component Verification

Including counterfeit detection and traceability validation.

All inspection services are conducted in line with IPC standards and are carried out by our experienced Master IPC Trainers.

Why Choose The Electronics Group for Your Electronics Inspection Needs?

Here at The Electronics Group, we care about your business, your goals and your success. That is why we build long lasting partnerships and support you from the very first conversation all the way to the final assessment and beyond. Here are a few of the main reasons why partnering with us will benefit you:

- IPC-certified Master Trainers delivering your electronics inspection services

- Non-destructive testing methods to save you money and resources

- Done for you inspection services or full training on the use of the machines yourself

- Full IPC-compliant defect reporting

- Latest high-resolution X-ray inspection technology

- Quick and efficient turn arounds, to keep you on track

Our services are designed to reduce waste, improve product quality, and give you confidence before delivery or deployment.

Flexible Electronics Inspection Services

You can access our electronics inspection services in whichever way works best for your business:

- Send your products to us — We’ll carry out the inspection and provide a full IPC-compliant defect report.

- Use our equipment — We offer equipment hire with full training provided if required.

- Tailored support — Short-term jobs, long-term partnerships, and ad-hoc inspections available, just let us know your needs and we will be ready.

Our inspection equipment is based in our Leeds training centre but we have supported clients across all the UK.

Get in Touch

Need support with an inspection project or want to learn more about how our services can help you reduce faults and improve quality?

You can call us on +44 (0)113 274 4270 to discuss your requirements. Alternatively, you can send an email to info@electronicsgroup.co.uk or click enquire now below.