A really good question that we get asked a lot is: What’s the difference between the IPC-A-610 vs IPC J-STD-001? And do I have to be certified in both?

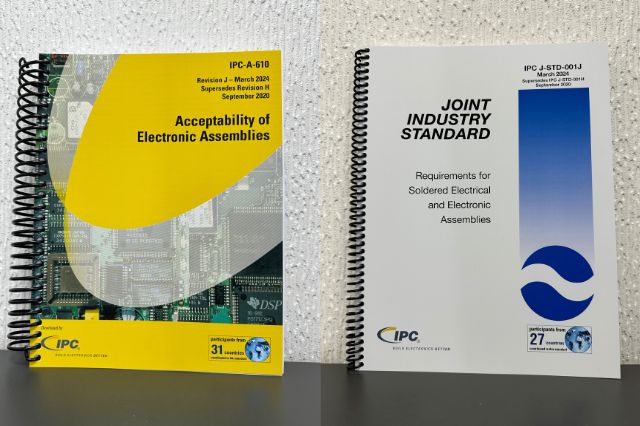

The IPC-A-610 and IPC J-STD-001 are two of the most globally recognised standards for the electronics industry. These standards are written by IPC, in conjunction with one another. Whilst having some crossover in context, they each serve distinct purposes and are applied at different stages of the manufacturing process.

This article will explore both the IPC-A-610 vs IPC J-STD-001, to summarise what is covered by each of the standards, who they are suitable for and their differences.

What is the difference between the IPC-A-610 vs IPC J-STD-001

IPC-A-610 Overview

IPC-A-610, the Acceptability of Electronic Assemblies, is the most widely used electronics assembly standard in the world. It is regarded as the gold standard for electronic assemblies and has gained global recognition as the source for end product acceptance and defect criteria for consumer electronics, as well as high reliability printed circuit assemblies.

The IPC-A-610 standard outlines the acceptability criteria for consumer-grade electronics, offering comprehensive visuals and guidelines that dictate what is considered a quality product. It covers topics like solderability, mechanical assembly and component installation.

IPC-A-610 certification is suitable for any company involved in the manufacturing of electronic assemblies, more specifically the inspection of electronics assemblies. Whether you are a small company focusing on consumer electronics or a large enterprise involved in complex industrial electronics production, IPC-A-610 offers the guidelines necessary to ensure product reliability and quality.

You can see more details about the IPC-A-610 course here.

It is important to note that the IPC-A-610 is not the standard to use during the actual PCB assembly process. That is where the IPC J-STD-001 comes in.

IPC J-STD-001 Overview

The IPC J-STD-001 covers the Requirements for Soldered Electrical and Electronic Assemblies. This standard has become known around the world for being the supreme standard for PCB assembly within the electronics industry. It’s emphasis lies in the manufacturing process itself. It outlines the requirements and acceptance criteria for soldering processes and materials, including component mounting, soldering methods and acceptability criteria. The course includes theory and practical elements.

IPC J-STD-001 is detailed, providing comprehensive criteria that cover various aspects of the PCB assembly process. It specifies methods for preparing materials, handling electronic components, and applying different soldering techniques.

Training and certification according to IPC J-STD-001 are considered essential for anyone involved in the assembly and soldering of electronic assemblies. This standard ensures that all who are involved in the soldering process are proficient and can produce assemblies that meet the required specifications.

You can see more details about the IPC J STD 001 course here.

Comparing the IPC-A-610 vs IPC J-STD-001 Standards

When looking at IPC-A-610 vs IPC J-STD-001, it’s important to understand that they complement each other rather than serve as alternatives. IPC-A-610 evaluates the finished product, whereas IPC J-STD-001 focuses on the process that leads to the finished product.

For manufacturers, integrating both standards into their manufacturing and quality processes is crucial. IPC J-STD-001 sets the groundwork during the assembly process, ensuring every step adheres to high standards. The IPC-A-610 then comes into play to verify that the final products meet the required visual and functional quality standards.

Implementing both standards can dramatically enhance the reliability of electronic products. You can read more on the importance of IPC certification in this article.

IPC-A-610 vs IPC J-STD-001 – Get Certified with The Electronics Group

Deciding between IPC-A-610 vs IPC J-STD-001 certification depends on your specific needs, job role and the nature of your products. If your focus is on the overall quality of electronic assemblies, IPC-A-610 is the standard to aim for. If your role involves PCB assembly then the IPC J-STD-001 is critical for ensuring that all soldering meets specific standards. As well as being good for assemblers, the J-STD-001 is very useful for process engineering.

At The Electronics Group we offer certification courses for both IPC-A-610 and IPC J-STD-001. Our expert Master Trainers ensure that your team not only learns the required standards but also understands how to implement them effectively.

We can deliver the training at either our Leeds or Cirencester training centres, or on site at your location. We are also fully flexible with course dates and payment options.

Get in touch with our team today to discuss your training needs or to receive a quote.

Whichever path you choose, The Electronics Group is here to guide you every step of the way.