In electronics manufacturing, ensuring the reliability of components and assemblies is critical. At the same time, damaging or destroying a product during testing is rarely an option. That’s where non-destructive testing (NDT) comes in. These non-destructive methods allow manufacturers to assess the quality and integrity of a component or assembly without affecting its performance or usability.

Non-destructive testing plays a key role in quality control, fault detection and product reliability, particularly in industries like aerospace, automotive, and medical, where electronics must perform without faults over long periods. You can read more about the benefits here.

In this article, we’ll cover the six most common types of non-destructive testing in electronics, including visual inspection, X-ray inspection, dye penetrant testing, ultrasonic testing, magnetic particle testing, and eddy current testing. Each has its own strengths and use cases, and many companies use a combination of these methods depending on the application.

Six Most Common Types of Non-Destructive Testing:

1 – Visual Inspection

Visual inspection is usually the first type of non-destructive testing used when it comes to identifying faults in electronic assemblies. This can involve simple visual checks by a trained technician or more advanced methods like using magnification, endoscopes or automated optical inspection (AOI) systems.

It’s particularly useful for spotting obvious defects such as soldering issues, component misalignment or visible cracks. While basic, it’s highly effective at catching problems early and guiding further testing if needed.

2 – X-Ray Inspection

Another invaluable type of non-destructive testing is X-ray inspection. This method takes things a step further by using X-ray imaging to allow us to look inside components and solder joints without dismantling the product. It’s especially useful for checking ball grid arrays (BGAs), multilayer PCBs and components with hidden joints or internal structures.

This technique can detect voids, misalignments, insufficient solder and even internal fractures.

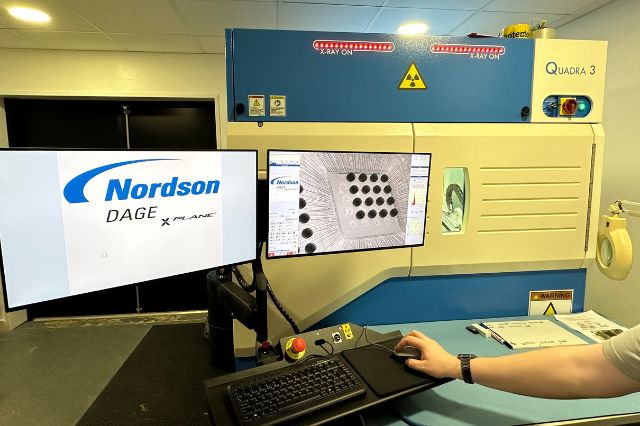

Here at The Electronics Group, we offer non-destructive X-ray inspection as part of our technical inspection services. Using our state-of-the-art Nordson Dage Quadra 3 X-ray system is a fast and reliable way to uncover faults that would be impossible to see with the naked eye.

Take a look at our non-destructive X-ray testing services.

3 – Dye Penetrant Testing

Dye penetrant testing is another common method, though it’s more often used for metal enclosures and external parts rather than the electronics themselves. A coloured dye is applied to the surface of the material and seeps into any cracks. After the surface is cleaned, a developer is applied to draw the dye back out, highlighting defects that would otherwise go unnoticed.

While not often used on the electronics themselves, it’s valuable for checking the integrity of cases, covers and mechanical parts that surround or support the electronics.

4 – Ultrasonic Testing

Ultrasonic testing uses high-frequency sound waves to detect internal flaws in materials. This method is more commonly associated with industrial components, but it has a place in electronics too. Particularly in identifying delamination in printed circuit boards.

A small probe sends sound waves through the material, and the way those waves bounce back helps the technician understand what’s happening inside. It requires specialist equipment and experience to interpret the results, but when used correctly, it can give a clear picture of structural integrity.

5 – Magnetic Particle Testing

Magnetic particle testing works by applying a magnetic field to a ferromagnetic material and then sprinkling fine magnetic particles (either solid or wet) over the surface. If there are any surface or near-surface cracks, the magnetic field will leak and particles will gather around them, making the fault visible.

This type of testing only works on certain metals and is typically used on frames, fixings or cases rather than the electronics themselves, but it plays a useful supporting role in making sure a full assembly is structurally sound.

6 – Eddy Current Testing

Eddy current testing involves using a coil to generate an alternating magnetic field. When this coil is placed near a conductive surface, it induces eddy currents in the material. If there’s a defect, the flow of those currents is disrupted, and the equipment picks up on that change.

It’s especially useful for detecting flaws in conductive coatings, finishes and layers on a PCB, and can be used without direct contact.

Non-Destructive Testing With The Electronics Group

Each of these six types of non-destructive testing has its own place depending on what’s being tested and at what stage of production. In practice, most manufacturers use a mix of techniques to get the best overall picture of quality.

Visual inspection might be used during early assembly, followed by X-ray or ultrasonic testing later on. In some cases, testing might be done as part of failure analysis, particularly if a product has failed in the field and a fault needs to be identified without destroying the sample.

At The Electronics Group, we work closely with clients to understand which inspection method suits their needs best. Our non-destructive X-ray testing is particularly popular with manufacturers who want high-resolution images of their assemblies without disrupting production. Alongside that, we can support with visual inspections to all to IPC standards.

Non-destructive testing helps manufacturers catch faults early, reduce returns and build better products. Whether you’re producing high-spec PCBs or working with complex electronic assemblies, these techniques are essential tools for quality control and the right approach can make all the difference.

Get in touch with us today and let’s discuss how we can work together to ensure your products are inspected to meet the highest standards.